As the industry has evolved and the repair industry has gotten more competitive, we have adapted an insatiable aftermarket, as it always demanding more. we believe constant innovation is the key to any successful company. With that, we assembled the best engineers and developers to build this technology in our very own factory to control output. Controlling the process of assembling the raw material allow us to control the cost and overhead.

While we wanted to set the new LCD standard, we didn't want that to come with the premium price tag. We wanted to create a whole new level of what you should expect out of an aftermarket LCD. Here is a deeper look at the production process of X04.

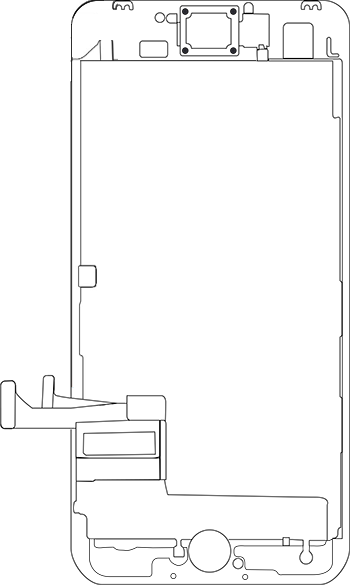

XO4 LCDs have been engineered to ensure that once installed into the housing, the frame and the front cover glass do not create a lip above the housing. A thicker material has been designed to ensure it meets OEM specification.

After testing hundreds of industry backlight manufacturers, we concluded that China and other manufacturers were not focusing on the critical factors to bring out the true colors of a LCD.We have built our own backlight technology and create the highest and brightest LCD to meet OEM Specification without sacrificing the battery consumption.

Aftermarket LCDs do not have to sacrifice small details like true and fake Force Touch.—What does this mean? XO4 has True Force Touch Panels installed on all iPhone 6s LCDs and above.

ESR Reflection paper is the film installed in the backlight, Currently in China, 98% of all LCD distribution are without ESR Reflection paper. XO4 doesn't cut corners! We ensured that every LCD comes with the authentic 3M ESR film.

The FPC Connector is a major issue with China LCDs (where the home button is bent and causes the home button not to function properly). We have avoided that problem by changing all the home button connectors to OEM FPC connectors.

Oleophobic coating isn't a new concept, however, China has been known to cut corners by simply spraying the glass with an oil to imitate the true oleophobic coating, which doesn't last more than 15-20 days. XO4 uses electroplating technology to adhere the oleophobic coating onto the front cover glass. This will guarantee that the coating will last over 300 days on normal usage.

XO4 LCD was designed with keeping the OEM specs in mind. XO4 is still a TFT panel, meaning that getting to the OEM quality is not going to be possible. However, we have gotten quite close. XO4 is best experienced when installing into a device and comparing the difference towhat the regular suppliers and China is offering. This graph will show where XO4 and the standard China copy LCDs stand when comparing them to OEM LCDs.

Over the last few years, we have seen the aftermarket lcds take over the repair industry. However, the technology has always been stagnant. 3 months ago we wanted to change this and the perception of what to expect. We started off by assembling the best engineers and developers in figuring out how to improve this. Our team decided in building our own factory to control the quality and raw material costs without the premium price tag. We are confident that X04 will be leaps and bounds better than what is currently expected in aftermarket lcds.

Here’s some videos with some comparison breakdown and what to expect out of X04.

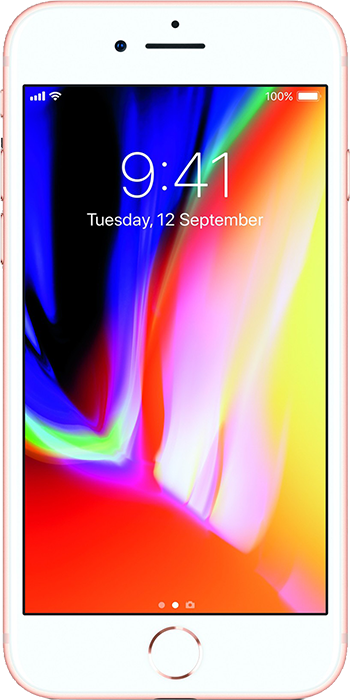

IPHONE 8 plus

IPHONE 8 plus IPHONE 8

IPHONE 8 IPHONE 7 plus

IPHONE 7 plus IPHONE 7

IPHONE 7 IPHONE 6s plus

IPHONE 6s plus IPHONE 6s

IPHONE 6s IPHONE 6 plus

IPHONE 6 plus IPHONE 6

IPHONE 6